The advantages of cold-formed steel profiles

The industrial construction sectors are constantly evolving. Regulatory pressure, cost-effectiveness, efficiency, and sustainability are important current topics that demand innovation and new ways of thinking. Cold-formed steel profiles have been a robust and flexible alternative to hot-rolled steel or concrete for decades. At KS Profile, we are seeing increasing interest in cold-rolled profiles from various sectors. In this article, we explain why.

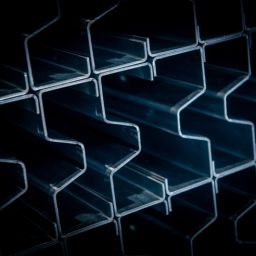

What are cold-formed steel profiles?

Cold-formed steel profiles are manufactured at room temperature by passing the steel through forming rollers that bend the material into the desired shape. This process ensures that the strength and flexibility of the steel are fully retained while allowing a wide range of shapes and sizes that meet specific requirements. Cold-formed profiles are extra strong due to the roll-forming process, providing a high load-bearing capacity and making them highly resistant to compressive forces.

Why are cold-formed profiles often a better alternative?

The application of cold-formed profiles offers several advantages:

Strength and Durability: As mentioned, the profiles are exceptionally strong, making them ideal for use in constructions that must withstand heavy loads. The use of steel profiles in the warehousing industry has long been standard practice.

Design Flexibility: Thanks to their versatility in shapes and sizes, architects and engineers can create creative and efficient solutions. For instance, we are seeing an increasing use of profiles in renovation, expansion, and building extension projects.

Ease of Assembly: Cold-formed steel profiles are easier to handle than traditional building materials. Firstly, they are lighter, making transport cheaper and allowing for faster processing. Additionally, custom-made hole patterns enable all profiles to be bolted together according to the design, which is faster and safer than welding.

Cost-Effectiveness: The production process for cold-formed steel profiles is efficient and less labor-intensive than, for example, hot-rolled profiles. This results in lower costs.

Sustainability: Cold-formed steel profiles are designed so efficiently that only the necessary amount of steel is used during production to fulfill the function of the profiles. This means that material is used very efficiently. Since cold-formed steel profiles are mostly bolted together, they can be easily dismantled and reused. Moreover, the steel used is fully recyclable. Today, profiles are also made from sustainably produced ‘green steel,’ which has a much lower carbon footprint than regular steel.

In which sectors are these profiles used?

Due to the many benefits that cold-formed steel profiles offer, they are widely used in various sectors, including construction, the automotive industry, the solar industry, and machinery. Their versatility makes them suitable for use in roof structures, wall frames, storage systems, trailers, and more.

At KS Profile, we take great pleasure in delivering high-quality cold-formed steel profiles that meet the specific needs of our customers every day. With a strong focus on quality, efficiency, and customer satisfaction, we strive to push our boundaries daily. Want to learn more about the possibilities of our profiles? Contact us today.

Get in touch

We would like to get to know you and your challenges and think with you to come up with the right solutions. Contact us and share your project needs!

.png?width=256&height=256&mode=crop&format=jpeg&dpr=1.0&signature=c1113c587762d98c65bd892c2412e2e139af26e7)